Environment [EN]

BES 6001 RESPONSIBLE SOURCING

WHAT IS INCLUDED IN THE SCOPE OF THE STANDARD?

This standard describes a framework for organizational issuess, supply chain management and environmental and social aspects that must be fulfilled in order to responsible sourcing of raw materials.

The standard requires a detailed description of procedures: responsible sourcing, supplier management system, monitoring of greenhouse gas emissions and energy consumption, efficient resource use, waste management and water abstraction and environmental impact of transport. The standard also refers to the issues such as human resource management, communication with local communities and business ethics. After the implementation the system is verified by an independent body.

WHAT DOES THE IMPLEMENTATION OF BES 6001 FOR RIGIPS?

Implementation of the standard will help our factory manage the impact on the environment throughout the supply chain. By implementing a standard, we can guarantee our customers that our products are made from raw materials sourced in a responsible manner and maintains the highest standard of quality and environmental safety.

By obtaining a certificate in accordance with the standard BES 6001, objects built with our panels can obtain extra points when applying for a prestigious BREEAM or LEED certificates.

Certificate BES 6001 also confirms the quality of our product, respect for the environment we live in and consideration of the customers and local community needs.

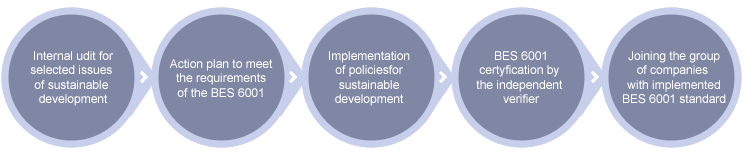

DEVELOPMENT AND IMPLEMENTATION

THE LIFE CYCLE OF THE PLASTERBOARD (ENVIRONMENTAL PRODUCT DECLARATION)

A useful tool to evaluate the environmental impacts of products

Life Cycle Assessment (LCA) is a structured analysis of the product's environmental impact throughout its life cycle. By "life cycle" we understand the stages through which the product passes, from the raw material extraction, production, transportation to the recycling stage. LCA is the assessment of the potential effects on the environment.

Analysis of the life cycle of a product are used in Type III Environmental Product Declaration (EPD). In a declaration we define environmental emissions (expressed in kg CO2) and environmental aspects such as energy and raw materials in the different stages of the product life. For example, for plasterboard production process emits 0,181kg CO2/kg of plasterboard.

WHY DO WE COUNT LCA?

In order to meet the needs of its customers, RIGIPS decided on a detailed analysis of their products in terms of environmental impact. By taking this step we want to show that we are transparent and environmentally friendly. In addition, thanks to the method used, transferred data are checked, comparable and ready to re-verify.

RIGIPS treats informing the customers about the environmental impact of products as a strategic element of social and environmental responsibility.

Additional benefits from the calculation of the LCA are:

- the opportunity to improve the product and reduce the costs of using the environment;

- the ability to compare the environmental impact with the other products;

- comparison of the environmental impact of raw materials used to manufacture the plasterboard;

- support for environmental reporting and certification (eg EMAS II, BREEM - environmental certification of buildings);

- promotion of our products based on reliable studies.

GREENHOUSE GAS EMISSIONS

MITIGATION OF CLIMATE CHANGE

In the Fifth Report of the IPCC (Intergovernmental Panel on. Climate Change working with organizations of the United Nations), it has been clearly stated that climate change is the result of human activity. Global warming is mainly caused due to greenhouse gases (especially carbon dioxide - CO2) emitted by burning fossil fuels. Scientists predict that a further growth in Earth's temperature will cause significant changes in our climate, and therefore it is necessary to reduce CO2 emissions. RIGIPS is one of the companies that operate in the European Trading Scheme Emissions (EU ETS) - which means that the factory is obligated to monitor and report greenhouse gas emissions and try to reduce it.

THE ANNUAL REPORT ON GREENHOUSE GAS EMISSIONS

In any activity, which contains the combustion of fossil fuels (such as coal or natural gas), there is also a greenhouse gas emissions. In RIGIPS we are monitoring direct emissions from combustion of fuels for the production of plasterboard and indirect - from electricity consumption. To meet our responsibilities for monitoring and reporting of emissions, every year we make an inventory of emissions and prepare an annual report which summarizes the size of annual greenhouse gas emissions from business operations. The document is prepared in accordance with the international standard ISO 14064 (standard for accounting and verification of greenhouse gas emissions). Each annual report is verified by the independent body – to ensure our clients that our emissions are properly measured.

THE BENEFITS OF REPORTING GREENHOUSE GAS EMISSIONS

With established procedures related to reporting on greenhouse gas emissions, we can evaluate the effectiveness of undertaken projects in order to reduce energy consumption and reduce CO2 emissions. It also allows us to identify the sources of emissions, to implement reduction plans, to reduce environmental impact and to build trust among our customers.

ENERGY EFFICIENCY

ENERGY MANAGEMENT ACCORDING TO ISO 50001

Energy efficiency is a key element of our policy. Improving the energy efficiency of our production process is our goal for the upcoming years, so we decided to implement ISO 50001 in our company.

WHAT IS A STANDARD ISO 50001?

ISO 50001 is an international standard defining the best practices in energy management. We put the economics of production in the first place and try to manage energy in a rational way. As part of the standard, our company is obliged to monitor and report energy consumption, carry out periodic inspections of energy, assessing future energy demand, identificate of sources having a significant impact on energy use. The standard provides high employee involvement in setting goals and measures for energy efficiency. RIGIPS energy objective is a reduction of at least one of the indicators of the energy result of at least 0.2% in comparison with 2015 by the end of 2018 years. RIGIPS is required to update aims, objectives and energy plans every 3 years.

Effective energy management according to ISO 50001 has an important influence on reducing energy consumption, reducing the impact of activities on the environment and reduce the costs associated with the purchase of fuel and electricity.

RESOURCE USE

SUSTAINABLE MANAGEMENT OF RESOURCES

At RIGIPS , we understand that effective management involves the management of available resources taking into account the need to reduce the impact of the use of these resources on the environment.

Among the resources we are trying to manage in the rational way there are: energy, waste, water and other materials used to produce our products (eg. limestone or paper).

To meet this requirement we undertook following obligations:

- saving the consumption of raw materials, mainly limestone;

- effective usage of materials, so that the same amount of product is obtained with less demand for feedstock;

- striving to use renewable resources;

- reducing waste and taking action to use them in the further production process.

WASTE MANAGEMENT

The consequence of our activities is waste production. We are trying to reduce the amount of the waste produced in our plant and we run selective collection in our factory. To ensure that the segregation is always carried out properly, we train our people and mark our waste containers.

Since 2012 we have been organizing segregation and recycling program "Collect and sort with RIGIPS". As a part of the program contractors who are using gypsum materials collect gypsum waste by putting them to a marked containers. After suitable preparation we are re-using the collected waste in our production processes.

WATER MANAGEMENT

Water is one of the most important raw materials used in our business. We are aware that water resources must also meet the needs of future generations and we are trying to minimize water consumption, both in the production process, as well as in everyday use at work and at home.

To allow free access to water for farmers whose fields are located next to our mine we want to make safe water intake in cooperation with municipal authorities.

RAW MATERIALS

We are constantly trying to reduce the amount of raw materials that we use to manufacture our products (plasterboard, gypsum blocks and gypsum ceilings). We do not want to waste valuable components of our products, which is why we develop technologies that allow us spending less raw materials for the same amount of products. As a result, our customers can be assured that the amount of limestone or paper used to produce their plasterboard or blocks was exactly the same as necessary.

TRANSPORT IMPACT

Our business is connected with the need to transport raw materials and products, as well as the movement of workers to and from the plant. To ensure that the process is not too disruptive to the environment we are committed to comply with certain rules, which allow us to control the negative impact of vehicles on the environment:

- Firstly, we take care of the safety of all vehicle drivers and other employees working in vehicles loading.

- We strive to shorten the length of the routes traveled and limit fuel consumption.

- We educate our employees and encourage them to use remote communication tools (phone calls, video conferencing, teleconferencing, etc.) or environmentally friendly transportation systems (eg. by bike).

To know whether our actions are effective, we monitor emissions into the air, noise and the leaks of oils and fuels from vehicles. As a result, we are able to control the impact of transport and to communicate our progress in reducing its environmental impact to the stakeholders.

TRANING AND EMPLOYEES DEVELOPMENT

The basic values of Saint-Gobain - the world leader in innovative materials with a wide range of applications - is the respect for humanity and the environment, which are the basis for sustainable development of the company. We believe that business is about people. The highest value of our company are satisfied employees who support and actively participate in the process of producing our materials.

INITIATIVES INVOLVING OUR EMPLOYEES

Solutions introduced in our organization serve our employees to actively participate in the processes of planning, implementation, maintenance and checking actions for continuous improvement. These are among others:

- "Safety Trophy" contest - award for the safe work of the most dedicated employees;

- Reporting of non-compliance - each employee has the opportunity to report any irregularities and observations related to health and safety, environment, quality and others. These reports are the basis for taking corrective or preventive action. The most active employees are rewarded.

- Behavioral audits (such as SMAT) - the goal is to eliminate inappropriate behavior, to increase employee awareness of safety and health at work, to minimize the risk of an adverse event. The audits involve all employees.

On the basis of current analyzes of staff training there are periodic evaluations provided for the employees and for executives.

AWARENESS OF THE IMPACT OF THE FACTORY’S ACTIVITIES

Each of our employees is aware, through appropriate training, that the current and potential impact on energy consumption and the environment depends on his actions and behavior in the field of sustainable development.

LOCAL COMMUNITIES ENGAGEMENT POLICY

REPORTING OF OUR BUSINESS

A very important element of our sustainable development policy is to live in harmony with the local community centered around our factory RIGIPS-STAWIANY. We know how important is inform and respond to queries of our neighbors to feel safe living close to our factory. That's why every year we will publish a report of corporate social responsibility (CSR), which discusses in detail our impact on the environment and local community.

In addition, we launched a special communication channel, through which anyone can direct question, complaint or a request concerning the activities of the factory. They can be submitted in writing. For every submitted question, complaint or a request, we answer within 40 days of its receipt.

ADDRESS FOR CORRESPONDENCE:

Factory RIGIPS- Stawiany

Szarbków 73

28-400 Pińczów